+86519-83550835

+86519-83550835

Introduction

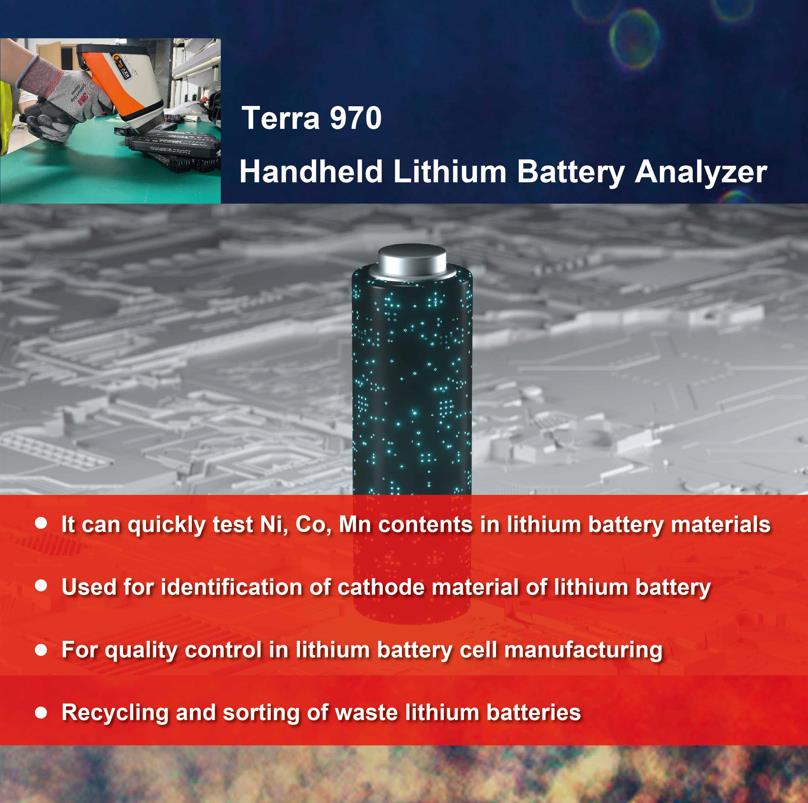

IntroductionTerra970 handheld lithium battery analyzer, based on advanced ceramic packaged microfocus X-ray tube and high-performance semiconductor detector, combined with advanced software algorithms, can quickly and accurately analyze Ni, Co, Mn and other regulated elements in lithium batteries. It is an ideal portable analyzer for lithium battery manufacturers’ process quality control and safety precautions, and for waste lithium battery recyclers’ sorting tasks.

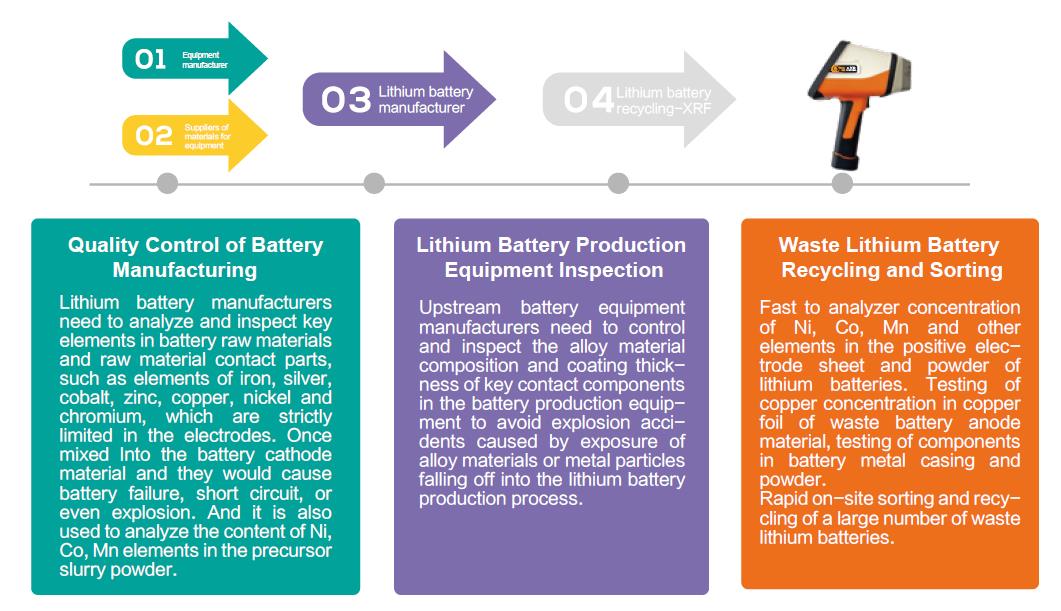

Quality Control of Battery Manufacturing

Lithium battery manufacturers need to analyze and inspect key elements in battery raw materials and raw material contact parts, such as elements of iron, silver, cobalt, zinc, copper, nickel and chromium, which are strictly limited in the electrodes. Once mixed Into the battery cathode material and they would cause battery failure, short circuit, or even explosion. And it is also used to analyze the concentration of Ni, Co, Mn elements in the precursor slurry powder.

Lithium Battery Production Equipment Inspection

Upstream battery equipment manufacturers need to control and inspect the alloy material composition and coating thickness of key contact components in the battery production equipment to avoid explosion accidents caused by exposure of alloy materials or metal particles falling off into the lithium battery production process.

Waste Lithium Battery Recycling and Sorting

Fast to analyze concentration of Ni, Co, Mn and other elements in the positive electrode sheet and powder of lithium batteries. Testing of copper concentration in copper foil of waste battery anode material, testing of components in battery metal casing and powder.

Rapid on-site sorting and recycling of a large number of waste lithium batteries.

Advantage

Advantage Application

Application Specification

Specification Related Article

Related Article Related product

Related product