As it is known, automobiles make our travelling convenient and make our lives easier. However, every coin has its two sides. The pollution produced by automobiles to people and nature is undeniable. Gases from exhausts cause serious damage to both human health and the environment. It causes air pollution. Therefore, catalytic converters have been used in automobile for approximately 45 years to largely decrease these gases released into the atmosphere.

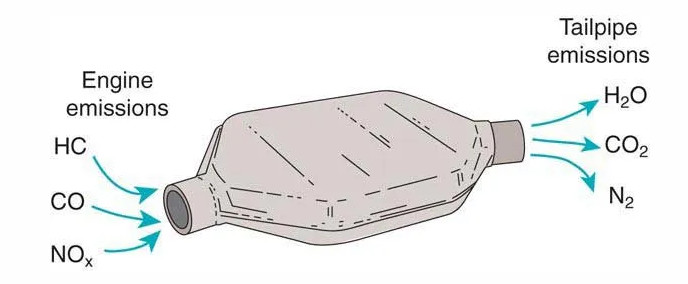

A catalytic converter uses a chamber called a catalyst to change the harmful compounds from an engine’s emissions into safe gases, like steam. It works to split up the pollution molecules in the gases that a car produces before they are released into the air.

Installed on the underside of a vehicle , the catalytic converter looks like a metal box. There are two pipes coming out of it. The convertor utilizes these two pipes and the catalyst during the process of making the emission gases safe to be exhausted.

Gases are brought in from the input pipe connected to the engine of a vehicle. These are blown over the catalyst, where chemical reaction happens as a result, it breaks apart the pollutants. The less-harmful gases now travel through the second pipe, or the “output,” that is connected to a car’s tailpipe.

In catalytic converters connected to the exhaust outlet pipe of cars, the platinum group metals convert carbon monoxide gas (CO), hydrocarbons (HC) and nitrogen oxides (NOx) released into the air into less harmful carbon dioxide (CO2) and water vapor. Catalytic converters contain platinum, palladium and rhodium precious metals from platinum group metals as catalysts.

It provides the breakdown of platinum and palladium hydrocarbons into water vapor and carbon dioxide. Rhodium converts nitrogen oxides and carbon monoxide into nitrogen and carbon dioxide.

As there are many types of car catalyst, the amount of PGM’s varies significantly. PGM here satands for platinum group metal. The fast and accurate testing method is required for the PGM’s content evaluation. Handheld or portable XRF analyzer provides precise and fast catalytic converters analysis for simple sorting and price evaluation. Usually, a concentration of PGM’s in a car catalyst is much higher, than in ores.

Typically there are 3 to 7 grams of platinum in a standard catalytic converter. A standard converter also contains 2 to 7 grams of palladium and 1 to 2 grams of rhodium.

A recycler will pay between $60 and $260 for a catalytic converter, with some going for $800 to $1,500 if they come from hybrid vehicles. Keep in mind that if your catalytic converter gets stolen, it could cost around $2,000 to replace it.

As we already know, three-way catalytic converter is the most important external purification device installed in the automobile exhaust system. The catalyst in the three-way catalytic converter can catalyze the oxidation-reduction reaction of carbon monoxide, nitrogen-hydrogen compounds and nitrogen-oxygen compounds in the automobile exhaust, reducing automobile exhaust pollution, which is an essential part of the automotive industry. Because the three-way catalyst contains platinum (Pt), palladium (Pd), rhodium (Rh) and other rare and precious metals, these metals can be recycled and reused and are conducive to environmental protection, so the recycling of the three-way catalyst and the identification of true and false need to be fast and effective analysis and detection methods.

With Terra900 Handheld XRF spectrometers, it takes just seconds to give the result comparing with hours or days as in a laboratory. Together with simple operation training and easy sample preparation, they are ideal and affordable solution for the daily business for quality control and price evaluation during catalyst’s dealing.

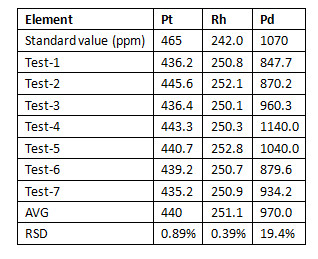

Following is the testing data for a catalyst standard to verify the testing stability of handheld XRF analyzer with a catalyst calibration.

AXR Scientific Terra900 series handheld XRF analyzers can be equipped with car catalyst calibration and provide fast, on-site analysis of spent car catalysts, with minimum sample preparation required. It can easily and reliably be used in the recycling and refining process of automotive catalytic converters to determine the concentration of platinum, palladium and rhodium. Besides, it can fast analyze other metal elements for the metal scrap from recycled automobiles to do scrap sorting job easily.

AXR Scientific is a high-tech manufacturer focusing on the development and application of X-ray technology products. It is committed to becoming a world-class supplier of X-ray industrial inspection solutions.AXR Scientific currently offer handheld XRF analyzer, handheld alloy analyzer, handheld soil analyzer, handheld lithium battery analyzer, precious metal analyzer, coating analyzer, gold analyzer and online XRF analyzer etc. to global customers. We keep serving global customers in the fields of machinery manufacturing, metal processing, aerospace, petrochemical, mining and geology, food safety, environmental protection, scientific research and etc. AXR Scientific keeps improving product performance and user experience with R&D advantages and innovative designs, and continues to provide global users with reliable X-ray measure solutions to solve various challenges from routine testing tasks to complex customized measure requirements. To contact us, please send email to market@axr-scientific.com