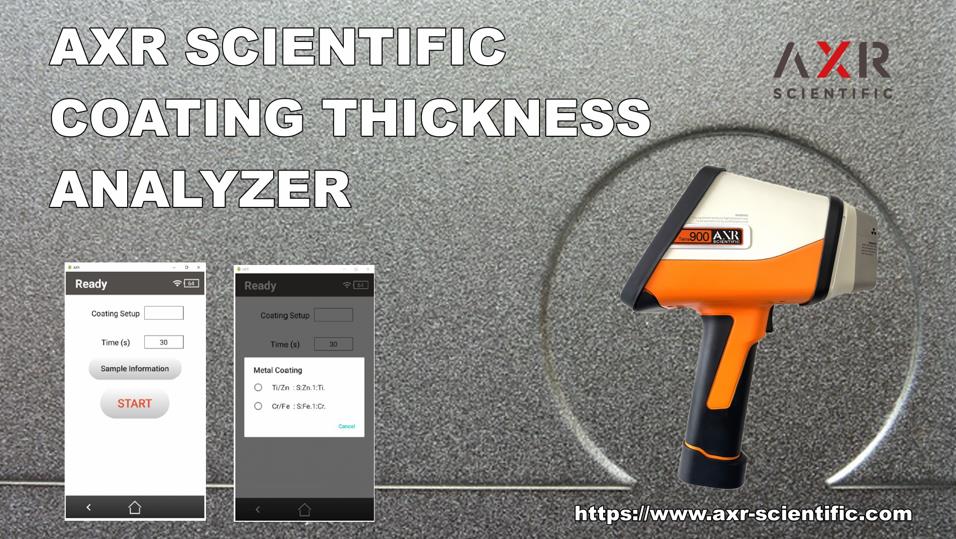

AXR Scientific Handheld XRF Analyzer Terra900 series can not only analyze the chemical composition of samples and when it is equipped with coating thickness testing mode, It is very useful to measure the thickness of coatings on metals and other substrates, like zinc plated steel, hot dipped zinc, tin plated steel, cadmium plated steel.

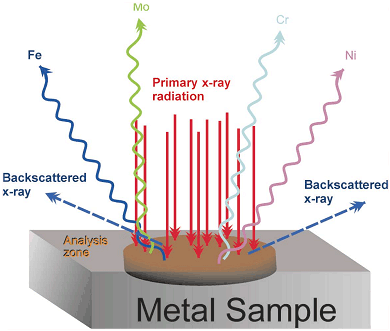

X-ray fluorescence (XRF) spectrometry is an useful technology to measure the thickness of metal layers.

The XRF method is based on the irradiation of a specimen using an X-ray tube and the measurement of the emitted X-ray characteristic from elements contained in the coating layers and the substrate. Because of the specificity of the measured signals for each element, XRF is suitable to measure the thickness in single and multiple layers of metal coatings over any type of substrate, making XRF more versatile than the other technologies.

The limitation of XRF is related to the thickness measurement of non-metal coatings like paint, which makes magnetic or eddy current gages more adequate for these measurements. However, XRF is capable of measuring the weight or the thickness of significantly thin coating layers of few atomic layers up to the saturation thickness (typically in the range of 6 to 60 µm), depending on the density, the average atomic number of the coating layer, and the energy of the emitted lines used.

In the past, You may see stationary or desktop XRF instrument has been used to measure coating thickness. However, the desktop XRF analyzers have limitation to measuring coating thickness on large and heavy parts if you don’t cut the sample. Now using handheld XRF analyzers, a well-established technology for metal and alloy identification and coating analysis have been so easy and convenient than ever before.

The most common type of coating measurement application is that of metallic coating on metallic substrate. This would be the case of zinc plated steel, hot dipped zinc, tin plated steel, cadmium plated steel

Coatings are widely used in the fields of automotive, aerospace, medical device, construction, and electronics.

Coatings have valuable properties to metal: corrosion resistance, wear-resistance, solderability, machinability, hardness, brightness, adhesive qualities, and lubricity.

Metal is often coated with a variety of substances, like zinc, nickel and chrome.

1. Zinc: Zinc works with a variety of substrates but is most often used to coat steel for protection against corrosion. There are many ways to apply zinc coating to steel but the most common are hot-dip galvanizing and continuous galvanizing.

2. Nickel: Nickel is a multi-purpose coating material; it’s aesthetically pleasing, corrosion-resistant, wear-resistant, stress-resistant, and magnetic. Nickel can be made to plate with little or no stress so it’s especially useful for electroforming or aerospace applications. Nickel is used for engineering applications to promote wearability, and it provides a barrier layer on coins, jewelry and circuit boards. On strip steel and in aerospace applications, nickel is used for low stress or for resizing.

3. Chrome: Chrome can work well on many substrates. Decorative chrome is used to improve appearance, while hard, or industrial, chrome offers excellent corrosion-, wear- and friction-resistance. Hard chrome is used in the nuclear, aerospace, and automotive industries as well as in the manufacture of many tools and medical devices.

The most common coating process is conventional electroplating. Other processes include electroless plating, galvanized coating, mainly applied to steel, iron, and aluminum, physical and chemical vapor disposition, anodizing, mechanical coating, pickling, etching, and sputtering.

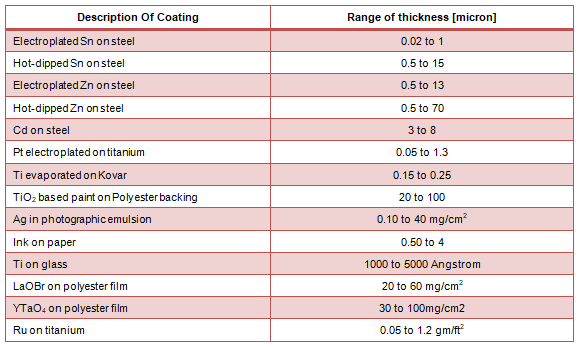

Examples of Coating Thickness Measurements by X-Ray

Coatings can serve a decorative, protective, or other functional purpose. For example, the automotive industry uses coatings for corrosion resistance, decoration, wear resistance, and to protect electronics. Similarly, the aerospace industry uses coatings that help minimize drag and prevent debris and build-up, saving on fuel consumption.

Accurate thickness measurements help factory deliver quality products while also controlling their coating costs. Coatings should be only as thick as they need to be to do their job. Making products with coatings that are too thick increases manufacturing costs. Customers also measure coatings for quality control on incoming materials by making sure that what they’re receiving is coated with the correct materials and at the right thickness.

XRF coating thickness measurement method is covered by international standards. Using a portable XRF analyser that is fast, efficient, and nondestructive helps provide quality control both on the product line and onsite.

AXR Scientific Handheld XRF analyzer can provide test results less than 15 seconds. Handheld XRF also does not damage the material being tested. Because the analyzer is small, portable, and handheld, it’s easy to test large samples that would otherwise have to be cut to fit into a desktop analyzer.

AXR Scientific Terra900 Handheld XRF analyzer can be used anywhere in the supply chain, from incoming inspection to confirmatory testing of completed subassembly parts, to final product quality control.

AXR Scientific is a high-tech manufacturer focusing on the development and application of X-ray technology products. It is committed to becoming a world-class supplier of X-ray industrial inspection solutions.AXR Scientific currently offer handheld XRF analyzer, handheld alloy analyzer, handheld soil analyzer, handheld lithium battery analyzer, precious metal analyzer, coating analyzer, gold analyzer and online XRF analyzer etc. to global customers. We keep serving global customers in the fields of machinery manufacturing, metal processing, aerospace, petrochemical, mining and geology, food safety, environmental protection, scientific research and etc. AXR Scientific keeps improving product performance and user experience with R&D advantages and innovative designs, and continues to provide global users with reliable X-ray measure solutions to solve various challenges from routine testing tasks to complex customized measure requirements. To contact us, please send email to market@axr-scientific.com