Residual Elements Analysis in Carbon Steel

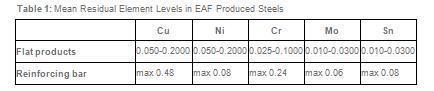

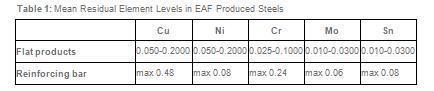

Residual elements (Cu, Ni, As, Pb, Sn, Sb, Mo, Cr, etc.) are defined as elements which are not added on purpose to steel and which cannot be removed by simple metallurgical processes. The presence of residual elements in steel can have strong effects on mechanical properties. There is therefore clearly a need to identify and to quantify the effects of residual elements in order to keep these effects within acceptable limits.

Why It is Important to Analyze the Residual Elements in Steel Piping

Residual elements, or at least some of them, have an influence on processing conditions and regimes, from casting to final annealing, and possibly on all mechanical properties. A clear distinction has to be made between those residual elements which have an effect due to their presence in solid solution, such as Mo, Cr, Ni, and Cu, and those which have an effect due to their segregation at interfaces (surface and grain boundaries), such as Sn, As, and Sb.Residual elements may influence on processing conditions and properties of steel products.

Effect of Residual Elements in Steel Piping for Refinery Industry

Residual element concentrations in carbon steel can be an important indicator in the lifetime and performance of pipes and components used in industrial applications, espeicially petrochemical applications. The elements generally include Cr, Cu, and Ni, as well as Mo, Sn, V, Sb, As, and Pb.

In the Refinery industry, HF alkylation units can be subject to selective corrosion resulting from elevated levels of residual Cr, Cu, and Ni. According to a study, a failure in the form of a pressure leak caused by internal corrosion was discovered at a weld between a 90° elbow and a straight section of pipe. With refinery inspector found that the sum of Cr, Cu, and Ni was higher than 0.50% comparing with a maximum allowable value of 0.20% for the sum of these three elements.

Why it is Necessary to Analyze RE for Refinery Industry

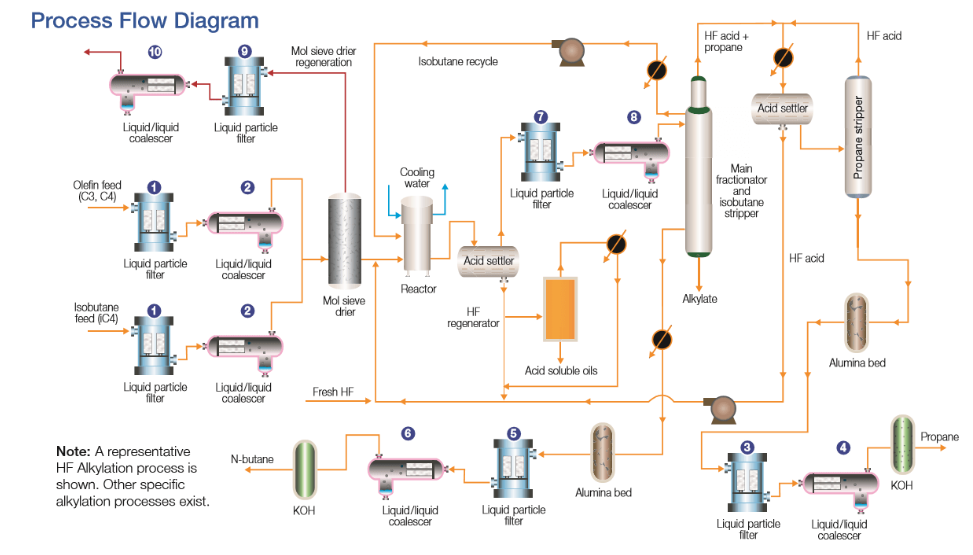

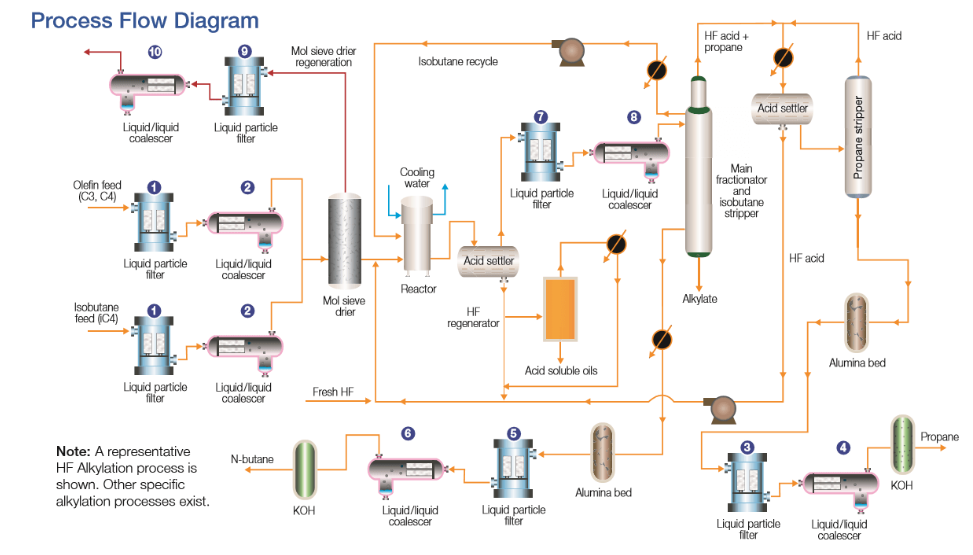

In the refining industry, HF alkylation is the increasingly important core process of production petrochemical products. The proper selection, application and placement of alloys in the process of process pipeline packaging is essential to avoid accidental corrosion and damage to the prevention of stress equipment components. Example studies have shown that the residual elements (RE) in carbon steel will speed up hydrofluoric acid corrosion, mainly including chromium, nickel, copper and other elements.

What is HF alkylation?

Hydrofluoric Acid (HF) Alkylation Units, often referred to as HF Alky units, are process units used in petroleum refining to convert isobutane and alkenes (primarily propylene or butylene) into alkylate, which is used to make gasoline.

Refinery inspectors need confidence in residual chemistry analysis. Residual concentrations can be critical to to accurately predict variances in material strength, hardness and corrosion resistance. HF alkylation is an increasingly central process in the refining industry for the production of petrochemical products.

AXR Scientific Handheld XRF Analyzer

Terra900S series HHXRF analyzers are high-performance X-ray fluorescence (XRF) metal analyzer. The light weight and small size reduce operator fatigue and enable access to more test points. Compact measurement geometry and a new powerful 5W X-ray tube and SDD detector provide highest performance and best sensitivity for the most demanding applications, such as residual element measurement. Terra900S offers the following key benefits:

(a)The handheld XRF analyzer is portable and easy to use on site

(b) No sample preparation required for non-destructive testing

(c) Fast and reliable quantitative analysis results with lower owning cost.

With the improved analytical capability for trace quantities of Cr, Cu, and Ni and other unique capabilities, AXR Terrr900 Handheld XRF analyzer is ideal for residual element analysis. In addition to residual elements, the analyzer can fast do chemical analysis and positive material identification for a wide range of alloy grades used in the oil and gas industry and nuclear and fuel power plant.

AXR Scientific is a

high-tech manufacturer focusing on the development and application of X-ray

technology products. It is committed to becoming a world-class supplier of

X-ray industrial inspection solutions.AXR Scientific currently offer handheld

XRF analyzer, handheld alloy analyzer, handheld soil analyzer, handheld lithium

battery analyzer, precious metal analyzer, coating analyzer, gold analyzer and

online XRF analyzer etc. to global customers. We keep serving global customers

in the fields of machinery manufacturing, metal processing, aerospace,

petrochemical, mining and geology, food safety, environmental protection,

scientific research and etc. AXR Scientific keeps improving product

performance and user experience with R&D advantages and innovative designs,

and continues to provide global users with reliable X-ray measure solutions to

solve various challenges from routine testing tasks to complex customized

measure requirements. To contact us, please send email to market@axr-scientific.com