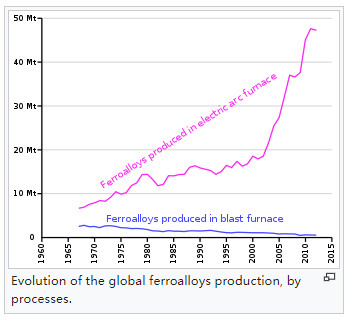

Ferroalloy means various alloys of iron with a high proportion of one or more other elements such as manganese (Mn), aluminium (Al), or silicon (Si). Ferro alloy are widely used in the production of steels and alloys The alloys add distinctive qualities to steel and cast iron or serve important functions during production and are closely associated with the iron and steel manufacturing industry, with the leading consumer of ferroalloys. The leading countries of ferroalloys producers erroalloys are China, South Africa, India, Russia and Kazakhstan, which accounted for over 80% of the world production.

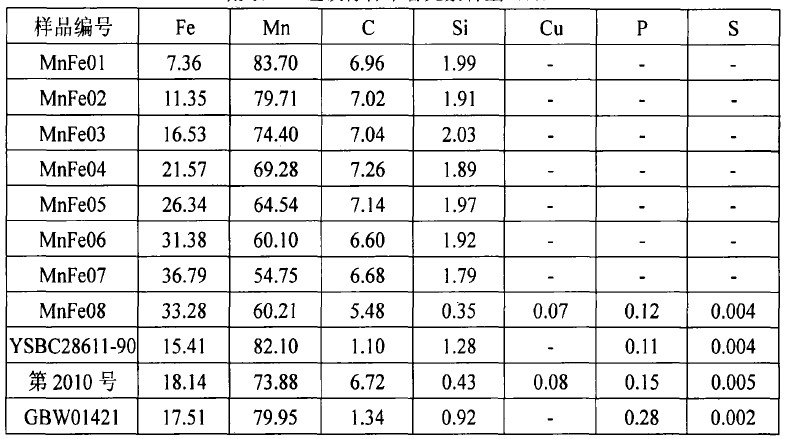

The common types of ferroalloy deoxidizers are ferrosilicon alloy, manganese-silicon alloy, and ferromanganese alloy. These three alloys are the top three alloys in the market in terms of output and consumption. In addition to deoxidation, they can also be used as alloy additives. By increasing certain metals, they can improve steel toughness, plasticity, corrosion resistance and other properties.

As ferroalloy is an important additive in the iron and steel smelting process, and its composition directly affects the quality of iron and steel products, so it is important for

fast and accurate analysis of ferroalloy chemical composition is very important.

Presently, “wet chemistry” is the most common method used to carry out precise analysis of ferroalloys. Yet, it has high labor costs and requires long sample preparation time.

For the analysis of FeSi alloys, X-ray fluorescence (XRF) spectrometry is an ideal alternative technique, providing high throughput and simple routine sample preparation.

The X-ray fluorescence analysis method has the advantages of fast analysis speed, wide detection range, stable and reliable results, etc. for the analysis of ferroalloys.

For a fast sorting, samples can be prepared as powders in cups. Pressed pellets are chosen as sample preparation when higher accuracy is required but special calibrations are necessary, especially if the grain size of the sample differs from available reference samples.

To avoid the influence of different grain sizes, the samples can also be prepared as fused beads. When preparing fused beads, the sample material must be oxidized to avoid damage of the platinum crucible. Standard operation procedures describe the process and list the required chemicals. With that approach even different types of ferro alloys can be analyzed with one method.

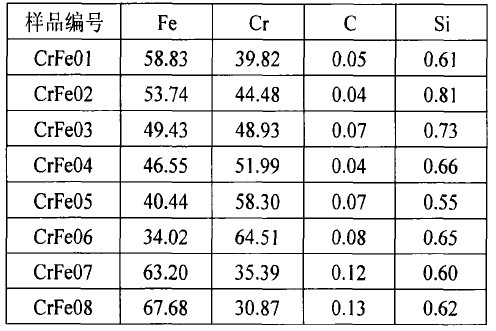

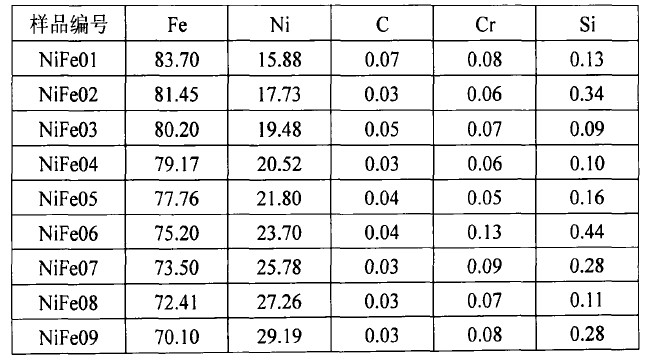

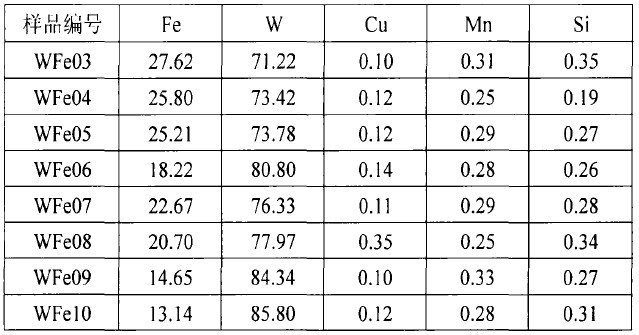

Elements concentration of ferrochromium

An energy dispersive X-ray fluorescence technology (ED-XRF) provides breakthrough advances in multi-elemental analysis of major, minor, and trace element concentrations. New developments in excitation and detection deliver outstanding sensitivity and detection limits with yielding remarkable results in precision and accuracy for ferroalloys.

Terra900 series handheld alloy analyzer can be a convenient inspection tool for element concentration analysis of ferroalloys and improves the efficiency of incoming ferroalloy material detection for steel plants.

In addition, Terra 900 Series handheld alloy analyzer also has the following advantages:

(a) The handheld XRF analyzer is portable and easy to use on site

(b) No sample preparation required for non-destructive testing

(c) Short detection time, reliable quantitative analysis results

The Terra900 series of handheld alloy analyzers provide a relatively complete solution for the quality monitoring and safety compliance testing. The instrument is equipped with high-performance X-ray tube and Si-Pin/SDD detector to provide users with fast and accurate element concentration analysis. In addition, an optional large-area silicon drift detector is provided to further improve instrument resolution and reduce analysis time.

AXR Scientific is a high-tech manufacturer focusing on the development and application of X-ray technology products. It is committed to becoming a world-class supplier of X-ray industrial inspection solutions.AXR Scientific currently offer handheld XRF analyzer, handheld alloy analyzer, handheld soil analyzer, handheld lithium battery analyzer, precious metal analyzer, coating analyzer, gold analyzer and online XRF analyzer etc. to global customers. We keep serving global customers in the fields of machinery manufacturing, metal processing, aerospace, petrochemical, mining and geology, food safety, environmental protection, scientific research and etc. AXR Scientific keeps improving product performance and user experience with R&D advantages and innovative designs, and continues to provide global users with reliable X-ray measure solutions to solve various challenges from routine testing tasks to complex customized measure requirements. To contact us, please send email to market@axr-scientific.com