Lithium-Ion Batteries Inspection

A lithium-ion or Li-ion battery is a type of rechargeable battery which uses the reversible reduction of lithium ions to store energy. It is the predominant battery type used in portable consumer electronics and electric vehicles. It also sees significant use for grid-scale energy storage and military and aerospace applications. Compared to other rechargeable battery technologies, Li-ion batteries have high energy densities, low self-discharge, and no memory effect.

Handheld electronics mostly use lithium polymer batteries (with a polymer gel as electrolyte), a lithium cobalt oxide (LiCoO2) cathode material, and a graphite anode, which together offer a high energy density.[ Lithium iron phosphate (LiFePO4), lithium manganese oxide (LiMn2O4 spinel, or Li2MnO3-based lithium rich layered materials, LMR-NMC), and lithium nickel manganese cobalt oxide (LiNiMnCoO2 or NMC) may offer longer lives and may have better rate capability. NMC and its derivatives are widely used in the electrification of transport, one of the main technologies (combined with renewable energy) for reducing greenhouse gas emissions from vehicles.

Safety Concern for Lithium-Ion Batteries in the Automotive Industry

Lithium-ion batteries are increasingly being used in high-power applications like electric vehicles However, with these innovations comes a critical safety concern: lithium-ion batteries have caused an increasing number of catastrophic incidents, such as fires and explosions. A short circuit is the cause of most lithium-ion battery accidents. The internal short circuit refers to the unintended contact between the positive and negative electrodes inside the battery

-Metal impurities introduced in the production process

-Burrs left from the cutting of electrode metal foils

-Lithium dendrites formed by battery use

-Squeezing and other kinds of unexpected mechanical stress

How the Handheld XRF can Secure the Production Process of Lithium Battery Manufacturing

Incoming raw material inspection

Many of the components used in the lithium battery production can be inspected by Terra970,

With CCD camera, the Terra970 analyzer can make an image of the material where the size and shape of any metal particles can be clearly seen. This indicates important information on the size and density of the contaminants for incoming inspection task. Meanwhile the XRF analysis of the contaminants tells you which elements are present, again this makes you understand well the contaminants present and these contaminants generally is highly related to actual battery performance.

Production process control

Another possible contaminants is from the production process itself. One way this can happen is from dust or metal parts scattered from production machinery or equipment. As well as identifying a source of contamination in the battery cell, this technique is useful to check for potential problems in the machinery itself; a change in the amount or type of dust emitted could mean that a service is due or a part needs replacing.

Failure cases analysis

The Terra970 can help to find out the root cause of battery failure during the final testing phase of manufacturing. You’ll be able to analyze products that have failed to see whether any metal particles are present on the cell separator or electrodes that could have caused a short circuit within the cell. Handheld XRF compositional analysis will tell you exactly which metals are present, which should help you identify where the contaminants came from.

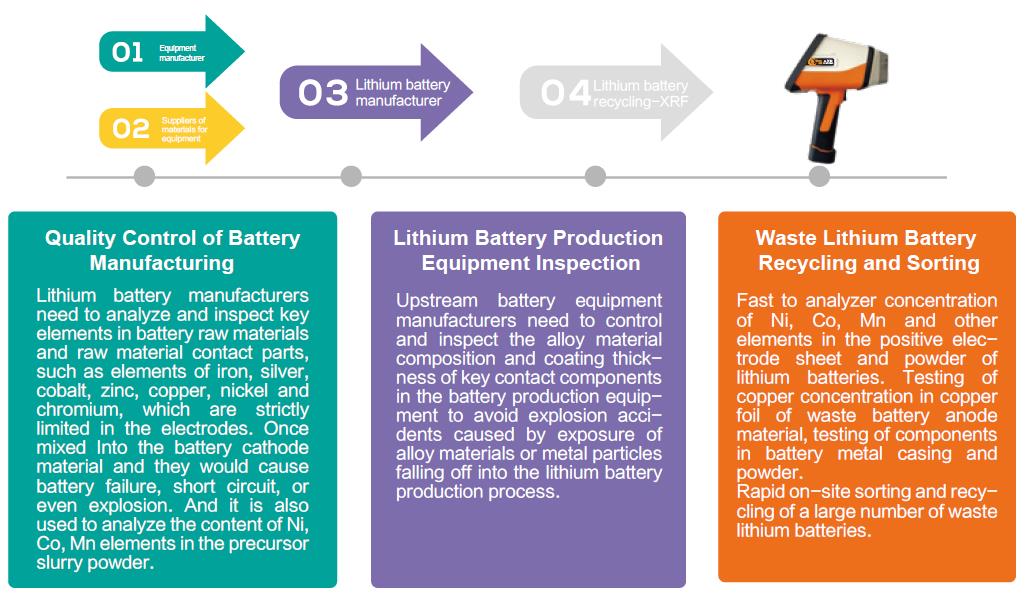

Handheld XRF Analyzers’ Value in the Lithium-Ion Battery Supply Chain

Handheld XRF analyzers can test key raw materials for batteries and battery contact parts in their production facility.

According to compliance requirements, the concentration of the metal elements ,including iron, silver, cobalt, zinc, copper, nickel, and chromium,in the lithium battery electrode materials are subject to certain limits. These limits are typically 30–50 ppm, because foreign metallic objects (even a very small amount) in lithium battery materials can cause a short circuit when the battery is in use.

Lithium battery manufacturer is strictly required to be free of any metal parts scattered about to prevent metal objects from being mistakenly introduced into the battery electrode materials.

Lithium raw material suppliers and battery manufacturing equipment suppliers also need to do this work to ensure that the same set of testing standards are followed throughout the entire supply chain (both upstream and downstream). Consequently, the lithium battery chain should have a strict control of the material quality in every stage. Even the lithium battery equipment supplier is also required to perform quality control tests on these components. In addition, the ternary lithium electrode materials commonly used in lithium-ion batteries can be recycled when the batteries reach end of life. Therefore the recyclers also need to test the elements concentration to decide the deal price.

Therefore a handheld XRF analyzers can be very helpful for all parties of the lithium-ion battery supply chain.

AXR Scientific is a

high-tech manufacturer focusing on the development and application of X-ray

technology products. It is committed to becoming a world-class supplier of

X-ray industrial inspection solutions.AXR Scientific currently offer handheld

XRF analyzer, handheld alloy analyzer, handheld soil analyzer, handheld lithium

battery analyzer, precious metal analyzer, coating analyzer, gold analyzer and

online XRF analyzer etc. to global customers. We keep serving global customers

in the fields of machinery manufacturing, metal processing, aerospace,

petrochemical, mining and geology, food safety, environmental protection,

scientific research and etc. AXR Scientific keeps improving product

performance and user experience with R&D advantages and innovative designs,

and continues to provide global users with reliable X-ray measure solutions to

solve various challenges from routine testing tasks to complex customized

measure requirements. To contact us, please send email to market@axr-scientific.com