+86519-83550835

+86519-83550835

Introduction

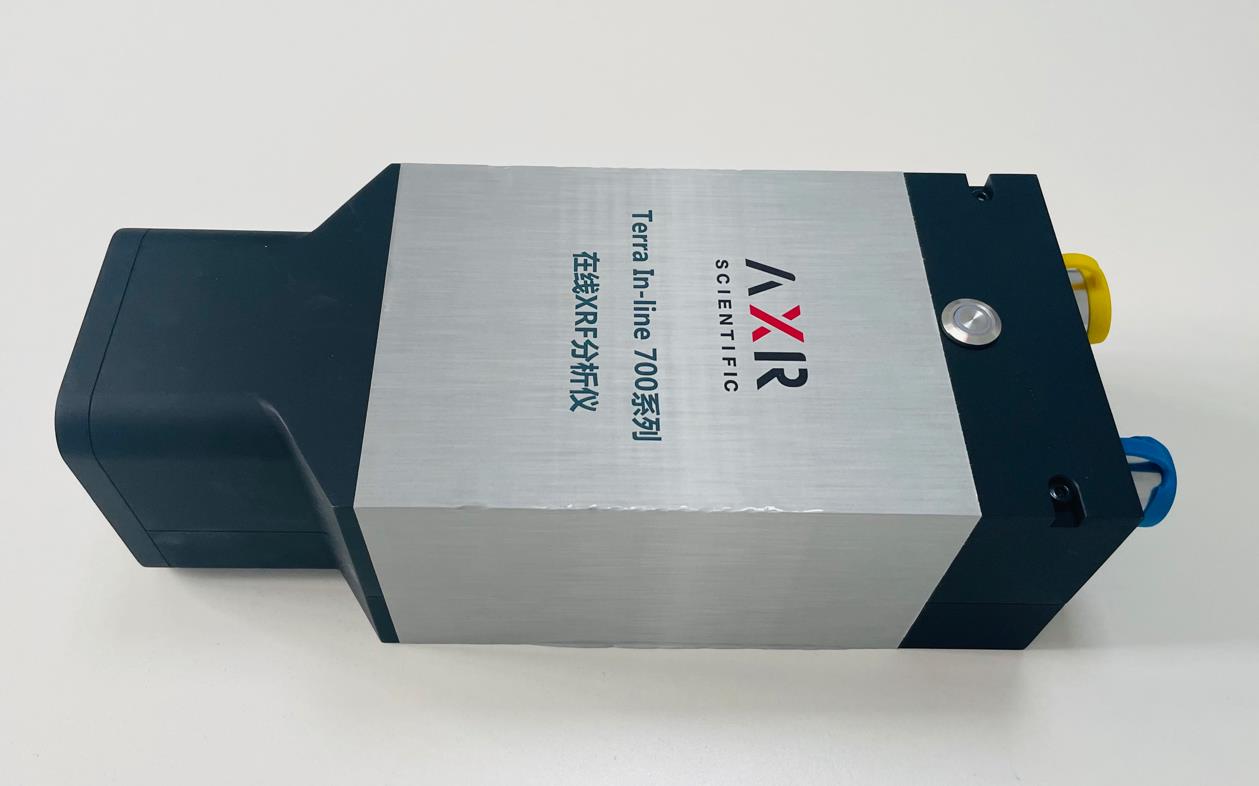

IntroductionAXR Scientific In-line XRF Spectrometer Module series can be flexibly configured, and can be effectively integrated with robotic arms and automatic devices according to the layout and actual situation of the factory production line to form an efficient detection solution that meets the characteristics of different samples. The whole process of detection is controlled by automation without too much human intervention. The entire online inspection solution can perform real-time inspection and quality control of production line products around the clock.

--24/7 operation

--It can realize mass production and 100% quality control of processed products

--Configured to provide pass/fail results, accurate alloy grades, and material chemical composition information

--Elemental analysis range: K19-U92 potassium to uranium, analyzable concentration range: 1ppm- 99.99%

--Fast analysis, results in seconds

--Rugged design, suitable for various environments

--Suitable for quality management of alloys, coatings, liquids and other materials

It can be used for real-time material composition detection of large quantities of metal bars, pipes, billet products and large quantities of machined parts in the process of metal production, processing, and 24-hour uninterrupted operation. For metal materials and parts used in automobile, aerospace, nuclear power and other industries, due to the need for safety, online complete inspection is selected instead of random inspection to ensure that the product quality is 100% up to standard. It can not only display the concentration and grade of chemical elements, but also conduct PASS/FAIL qualified testing.

The sorting of ore and the control of ore grade in the mining process are very important. Terra In-line XRF analyzer 700 can be flexibly configured to analyze the ore on the conveyor belt, which can greatly improve the analysis efficiency and ensure the consistency of ore grade. . The cost of raw materials is saved, the production efficiency is improved, and the rapid recovery of equipment input costs can be achieved.

In addition to being used for solid online composition analysis, Terra In-line700 series can also perform online real-time detection of solid film thickness, such as metal coating, solar cell coating, copper tin plating, etc. It can also be used for online composition analysis of liquids or fluids, such as electroplating Liquid, online analysis of copper foil industry, etc.

Advantage

Advantage Application

Application Specification

Specification Related Article

Related Article Related product

Related product