In the landscape of material analysis, few tools are as versatile and indispensable as X-ray Fluorescence (XRF) lab equipment. Once a specialized instrument confined to high-end geology labs, modern XRF analyzers have evolved into critical assets across a breathtakingly wide range of industries. Their core superpower—providing rapid, non-destructive elemental composition analysis—makes them the go-to solution for quality, safety, and efficiency from the raw earth to the finished product.

Let's journey through the diverse world of modern XRF lab equipment and see how it powers key sectors of the global economy.

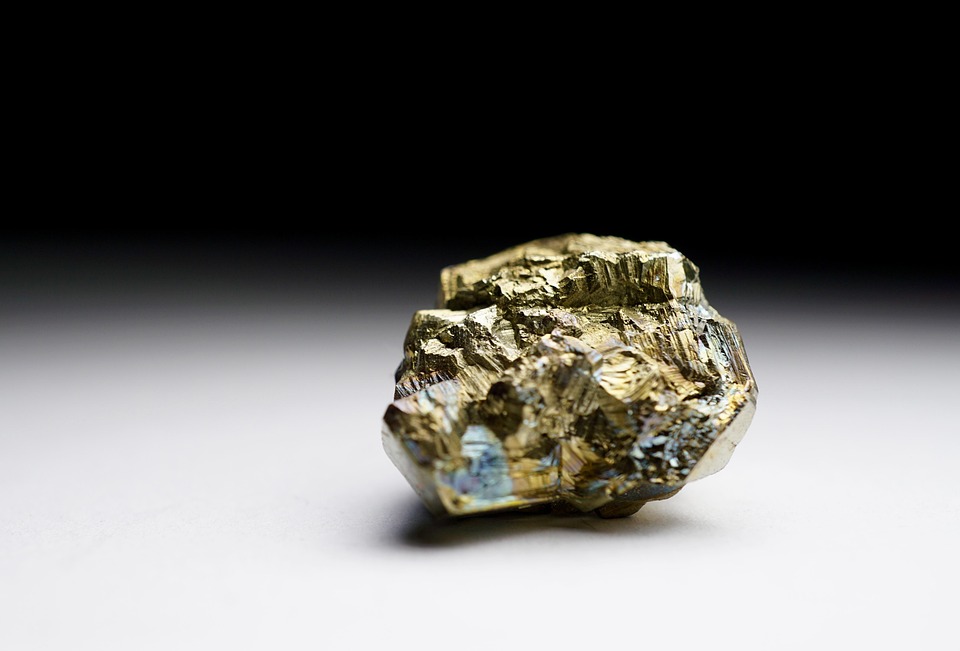

This is where XRF technology earned its stripes. In mining exploration and operations, speed and accuracy are paramount.

Exploration & Prospecting: Portable and benchtop XRF analyzers provide real-time, on-site analysis of soil, drill cores, and rock samples. This allows geologists to map ore body boundaries, identify mineral species, and make critical "drill or don't drill" decisions without waiting weeks for off-site lab results.

Grade Control: In active mines, XRF is used to quickly sort high-grade ore from low-grade material and waste, optimizing the feed to processing plants and maximizing resource recovery.

Environmental Monitoring: It also plays a role in analyzing potentially toxic elements in mine tailings and surrounding soil, ensuring compliance with environmental regulations.

From foundries to aerospace manufacturing, the precise chemistry of metals is non-negotiable. XRF lab equipment sits at the heart of this process.

Incoming Material Inspection: Verifying the composition of scrap metal or raw alloys before they enter the melt prevents costly formulation errors.

Process Control: During production, XRF provides rapid analysis of molten metal or finished products (like sheets, pipes, or wires) to ensure they meet exacting ASTM, ISO, or customer-specific standards (e.g., 304 vs. 316 stainless steel, or specific aluminum or titanium alloys).

Positive Material Identification (PMI): This is critical for safety in oil & gas, chemical plants, and power generation. PMI using handheld or benchtop XRF verifies that installed pipes, valves, and vessels are made from the correct alloy, preventing catastrophic failures due to material mix-ups.

The products we use every day rely on XRF for safety, performance, and regulatory compliance.

RoHS & Hazardous Substance Compliance: XRF is the primary screening tool for Restriction of Hazardous Substances (RoHS), Consumer Product Safety Improvement Act (CPSIA), and other regulations. It can quickly detect restricted elements like lead, cadmium, mercury, and bromine (from flame retardants) in plastics, coatings, solder, and finished electronics.

Catalyst and Battery Analysis: The precious metal loading in automotive catalysts (platinum, palladium, rhodium) is precisely measured with XRF. Similarly, it's used in the development and quality control of battery components, analyzing cathode materials for lithium, cobalt, nickel, and manganese.

The circular economy depends on efficient sorting and purification. XRF is a recycling plant's best friend.

Metal Scrap Sorting: It instantaneously identifies and sorts ferrous and non-ferrous alloys—separating copper from brass, aluminum from magnesium, and identifying high-value nickel alloys—dramatically increasing scrap value and purity.

E-Waste Processing: XRF helps recover precious metals (gold, silver) from circuit boards while also screening for hazardous materials that need special handling.

Soil and Water Analysis: Environmental labs use high-sensitivity benchtop WDXRF (Wavelength Dispersive XRF) equipment to detect trace levels of contaminants like arsenic, selenium, or heavy metals in soil, sediments, and filtered water samples.

Even the infrastructure around us is shaped by XRF analysis.

Cement and Clinker Production: The final properties of cement are dictated by its precise elemental makeup (Ca, Si, Al, Fe). Online and lab-based XRF systems provide minute-by-minute control of the raw meal and kiln feed, ensuring consistent product quality and optimizing energy use.

Glass and Ceramics: From the color of glass (controlled by iron, chromium, cobalt) to the durability of ceramics, XRF ensures batch-to-batch consistency and verifies that raw materials like feldspar, silica sand, and kaolin are within specification.

Petroleum and Refining: XRF analyzes sulfur content in fuels to meet environmental standards and measures additives and wear metals in lubricating oils, which is critical for engine health monitoring.

The AXR Terra900 series is an excellent handheld analyzer for rapid, non-destructive metal analysis across various fields. Utilizing advanced electronics and algorithms, it delivers lab-quality results in seconds with minimal training or sample preparation, suitable for solids, liquids, and powders. It is ideal for alloy identification, quality control, scrap recycling, and PMI applications.

Modern XRF lab equipment is far more than a single-purpose tool. Its evolution from bulky lab units to sophisticated, user-friendly benchtop and even portable systems has democratized elemental analysis. Whether it's ensuring the gold in a microchip is pure, the steel in a skyscraper is strong, the toy on a shelf is safe, or the new mine is viable, XRF provides the fundamental data that drives quality, innovation, and sustainability across the entire industrial spectrum. From the depths of the mine to the palm of your hand, XRF is the silent guarantor of material integrity.