Catalytic converters, crucial components in automotive exhaust systems, play a pivotal role in reducing harmful emissions and promoting environmental sustainability. However, when these converters reach the end of their useful lives, they often hold a hidden treasure trove of valuable materials, such as precious metal catalysts like platinum, palladium, and rhodium. Properly identifying and recycling these catalytic converter scraps has become a crucial endeavor, not only to recover valuable resources but also to minimize environmental impact. This is where portable analyzers step in, revolutionizing the process.

Catalytic converters are designed to transform toxic gases like carbon monoxide, nitrogen oxides, and volatile organic compounds into less harmful substances like nitrogen, water vapor, and carbon dioxide. Due to the presence of precious metal catalysts, catalytic converters have substantial economic value even after their primary purpose is fulfilled.

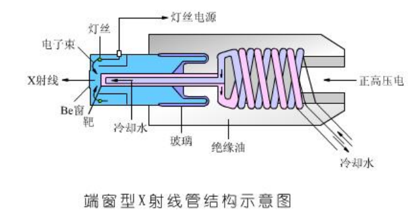

Portable analyzers have transformed the way we identify and recycle catalytic converter scrap. These devices utilize advanced technologies like X-ray fluorescence (XRF) and laser-induced breakdown spectroscopy (LIBS) to quickly and accurately determine the elemental composition of materials. Here's how they contribute to the process:

Traditional methods of analyzing scrap materials often require sending samples to laboratories, causing delays. Portable analyzers provide real-time, on-site analysis, enabling swift decision-making in recycling processes.

Portable analyzers are non-destructive, meaning they analyze materials without damaging them. This is critical when dealing with potential sources of precious metals, ensuring their integrity.

Portable analyzers reduce the need for extensive sample preparation and transportation to distant labs. This expedites the recycling process and saves costs.

By quickly and accurately identifying the presence of precious metals, portable analyzers aid in sorting valuable materials from other components of catalytic converter scrap.

These analyzers help ensure compliance with environmental regulations. By precisely identifying materials, they help processors avoid inadvertently mishandling hazardous substances.

AXR Scientific Terra900 series handheld XRF analyzers can be equipped with car catalyst calibration and provide fast, on-site analysis of spent car catalysts, with minimum sample preparation required. It can easily and reliably be used in the recycling and refining process of automotive catalytic converters to determine the concentration of platinum, palladium and rhodium. Besides, it can fast analyze other metal elements for the metal scrap from recycled automobiles to do scrap sorting job easily.

AXR Scientific Terra900 portable alloy Analyzer or handheld xrf gun provides maximum efficiency in the analysis and sorting of metal alloys. Due to its speed, non-destructive nature and minimal requirements for sample preparation, because XRF is more versatile and convenient than the optical emission method.

The FP method is applicable to all existing types of alloys, which makes it indispensable in metallurgy, foundry, mechanical engineering and other areas.

Fast and onsite analysis of the composition of alloys is carried out when scrap yard performing the following works, which is not only involves in the scrap yards but also the buyer of the scrap and foundry and metal factories.

The advent of portable analyzers has revolutionized the identification and recycling of catalytic convertor scrap. These devices streamline the process, making it faster, more accurate, and environmentally friendly. By unlocking the hidden value of catalytic converter scrap through proper recycling, we not only recover precious materials but also contribute to a more sustainable and resource-efficient future.