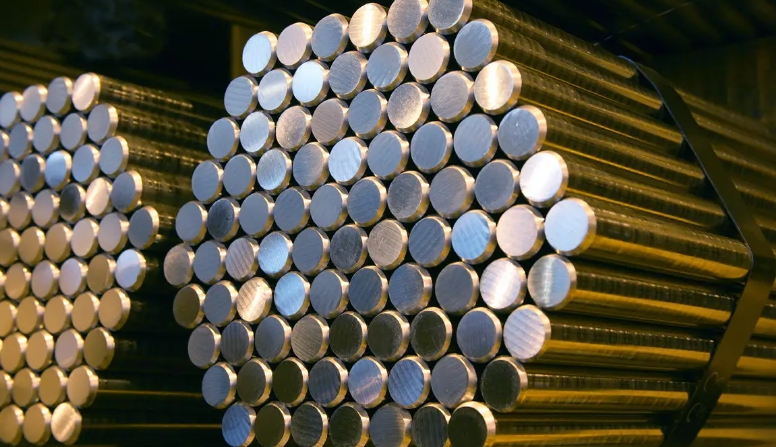

In an increasingly materials-dependent world, accurate metal analysis is crucial for various industries, from aerospace and automotive manufacturing to the manufacturing and construction sectors. Traditional methods of metal analysis involve sending samples to a laboratory, a process that can be both time-consuming and expensive. However, recent technological advancements have provided a more efficient and convenient solution to address this challenge: portable alloy analyzers. In this article, we will delve into the potential of these innovative portable devices to explore the future of metal analysis.

Portable alloy analyzers, also known as handheld X-ray fluorescence (XRF) analyzers, have gained significant popularity across various industries due to their numerous advantages, including portability, rapid results (providing real-time data), non-destructiveness, cost-effectiveness, and user-friendliness. Given these significant advantages, portable alloy analyzers find applications in a wide array of industries, including metallurgy and manufacturing, mining and exploration, construction, environmental compliance, and more. While these are not limited to these industries, professionals from different sectors can appreciate the immense utility and potential of portable alloy analyzers from their respective professional perspectives.

Market-leading brands include Olympus, Thermo Fisher Scientific, Bruker, Rigaku, Hitachi High-Tech, Niton (Thermo Scientific), AXR, and many more. These brands offer a variety of models of portable XRF analyzers to cater to diverse application needs. They play a crucial role in quality control, mining, environmental monitoring, laboratory analysis, and other fields. The choice of the appropriate brand and model typically depends on specific application requirements and budget considerations.

AXR Terra900 series is a good choice for metal analysis in many fileds, delivering rapid, accurate results right in your hand. Due to the advanced electronics and state-of-the-art mathematical algorithms, Terra900 series provide ultimate quality of measurement within a couple of seconds, which makes it an ideal solution for checking and analyzing incoming material, finished goods and in process production parts with a non-destructive way. With operating simplicity, you can view the alloy grade and chemistry on the touch screen display with just a few seconds to obtain lab-quality chemistry, requiring minimal training and little or no sample preparation for all shape and size of sample.Terra900 handheld applications are not limited to solid but can also measure liquids and powders . Terra900 series handheld alloy analyzer are wildly used for alloy grade identification and quality control, scrap metal recycling, precious metals, PMI and so on.

Taking the field of scrap metal recycling as an example, the AXR Terra900 series finds widespread application in this domain due to its outstanding performance. Just in terms of the variety of alloys, it can detect Magnesium alloys, Aluminium alloys, Titanium alloys, Stainless steels, Low alloy steels, Tool steels, Cobalt alloys, Nickel alloys, Copper alloys, Zinc alloys, Precious alloys, Brasses, Bronzes, and more, including but not limited to those listed. In various aspects of the entire field's application, handheld alloy analyzers are employed in the following areas: sorting and separation of ferrous and non-ferrous scrap, input control of materials, including Ferroalloys, confirmation of grades of steels and alloys, composition control during melting, certification analysis of metallurgical products. Hence, it holds a pivotal position in the scrap metal recycling industry.

As technology continues to advance, the potential for handheld alloy analyzers will only grow:

Improved Accuracy: Ongoing research and development are aimed at enhancing the accuracy of these devices, enabling even more precise metal analysis.

Data Integration: Integration with cloud-based systems and data sharing will enable better collaboration among teams, streamline decision-making processes, and provide a historical record of analysis.

Expanded Material Coverage: Future handheld analyzers may extend their capabilities to analyze a broader range of materials, making them even more versatile.

Artificial Intelligence: Incorporating AI algorithms will help in the interpretation of complex data, making it easier for operators to obtain meaningful insights from the results.

In the next 50 years, I predict that handheld alloy analyzers will be the most widely used in the fields of environmental monitoring and regulatory compliance. With the enhancement of environmental awareness and concerns about environmental pollution, as well as concerns about resource sustainability, these analyzers will become more important. They will be used to analyze the metal content in soil, water, air, and waste to ensure environmental compliance, monitor and manage pollution, and support sustainable development goals.

This is predicted due to factors such as increasing environmental pollution issues, increasing regulatory compliance, and the importance of protecting the Earth's environment and resources emphasized by the Global Sustainable Development Goals (SDGs). Therefore, due to the increasing importance of environmental protection and regulatory compliance, as well as the continuous development of technology, handheld alloy analyzers will be the most widely used in the field of environmental monitoring and regulatory compliance in the next 50 years, To ensure the health and sustainability of the environment.

The future of metal analysis is indeed bright, thanks to the evolution of handheld alloy analyzers. These devices offer a practical, cost-effective, and efficient solution to the challenges of metal analysis, benefiting a wide array of industries. With ongoing advancements and the potential for even greater capabilities, it's clear that the future of metal analysis is in the palm of our hands. As technology continues to advance, these handheld devices will play an increasingly important role in maintaining the quality, safety, and innovation of materials in our ever-evolving world.