Catalytic converters, those inconspicuous components nestled within our car's exhaust system, play a pivotal role in reducing harmful emissions. However, their value extends far beyond environmental benefits; they are also profitable commodities in the scrap market. Equipped with precious metals, primarily platinum, palladium, and rhodium, they act as catalysts to transform noxious emissions into less harmful substances. The recycling industry has recognized the high intrinsic value of these metals, driving the demand for scrap catalytic converters. Therefore, understanding the pricing dynamics of these automotive components is crucial for both sellers and buyers.

There are numerous factors influencing scrap catalytic convertor prices, such as metal content, purity and quality, market prices, converter size and type, relevant regulations, buyer reputation, and more. Of these, the metal content, purity, and quality are particularly critical. The primary determinants of the scrap value of catalytic converters are the metals they contain. Their composition varies between manufacturers and models, significantly affecting prices. Some catalytic converters may contain more precious metals than others, hence commanding higher prices in the scrap market. Converters with higher levels of platinum, palladium, and rhodium will fetch better prices. The condition of the catalytic converter should also be considered; damaged or contaminated units may receive lower valuation.

To detect concentration, discern purity, and assess quality, instruments designed for detecting precious metal content have become essential. There are many handheld metal analyzers available on the market that can be used for this purpose. Handheld alloy analyzers play a significant role in evaluating the value of catalytic converters and upholding market integrity. They offer a swift, accurate, and reliable method for determining the precious metal content within these devices, contributing to fair and legal transactions.

With Terra900 Handheld XRF spectrometers, it takes just seconds to give the result comparing with hours or days as in a laboratory. Together with simple operation training and easy sample preparation, they are ideal and affordable solution for the daily business for quality control and price evaluation during catalyst’s dealing.

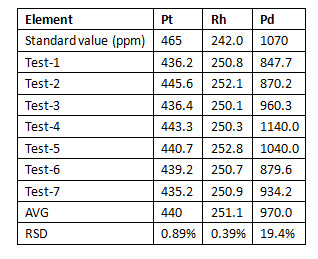

Following is the testing data for a catalyst standard to verify the testing stability of handheld XRF analyzer with a catalyst calibration.

AXR Scientific Terra900 series handheld XRF analyzers can be equipped with car catalyst calibration and provide fast, on-site analysis of spent car catalysts, with minimum sample preparation required. It can easily and reliably be used in the recycling and refining process of automotive catalytic converters to determine the concentration of platinum, palladium and rhodium. Besides, it can fast analyze other metal elements for the metal scrap from recycled automobiles to do scrap sorting job easily.

The AXR Terra900 series is an excellent choice for metal analysis in many documents and provides fast and accurate results. With advanced electronic technology and the latest mathematical algorithms, the Terra900 series provides high-quality measurements in seconds, making it an ideal solution for non-destructive testing and analysis of materials, finished products, and unfinished products. The practice is very simple. You can view the alloy level and chemical composition on the touch screen within a few seconds to obtain laboratory quality chemical composition, with little or no need to prepare samples for various shapes and sizes.

The X-ray Fluorescence Spectrometry (XRF) technology holds significant and promising prospects in the field of scrap catalytic converters. Here are the future prospects of XRF technology in this domain:

Enhanced Efficiency in Scrap Catalytic Converter Recycling: XRF technology can further elevate the efficiency of scrap catalytic converter recycling. In the future, we may witness the development of more portable and high-performance XRF instruments, enabling recycling businesses to analyze and categorize scrap catalytic converters swiftly and accurately. This will contribute to increased resource recovery rates and reduced waste of catalytic converters.

Precise Metal Recovery: As the prices of rare metals rise, and metal resources become increasingly scarce, XRF technology may be used for more precise recovery and separation of precious metals within scrap catalytic converters. This will enhance resource utilization efficiency and reduce reliance on finite resources.

Environmental Compliance Monitoring: The recycling and processing of scrap catalytic converters require compliance with environmental regulations to mitigate adverse environmental impacts. In the future, XRF technology may be applied to a broader spectrum of environmental compliance monitoring to ensure that the recycling process aligns with legal regulations and environmental protection standards.

Data Analysis and Smart Integration: In the future, XRF technology may be combined with data analysis and Artificial Intelligence (AI) techniques to better interpret analysis results and provide decision support. This will improve the categorization and pricing of scrap catalytic converters and enhance the management of scrap materials.

International Collaboration: With the global scrap catalytic converter market continuously expanding, XRF technology may become a crucial domain for international collaboration. Researchers and businesses from different countries and regions can share best practices and technologies to promote the globalization and sustainability of the scrap catalytic converter recycling industry.

So, the future prospects of X-ray Fluorescence Spectrometry in the field of scrap catalytic converters include improving recycling efficiency, facilitating sustainable resource utilization, enhancing environmental compliance, and integrating data analysis and smart technology. This will drive the development of the scrap catalytic converter recycling industry while contributing to global resource management and environmental protection goals.

Scrap catalytic converter prices are influenced by a complex interplay of factors, ranging from metal content to market dynamics. Understanding these variables is essential for those looking to sell or purchase scrap converters in this thriving market. As the demand for recycling and sustainability continues to grow, the value of these unassuming auto parts in the scrap market is likely to remain a lucrative investment. Whether you're an individual looking to sell a used converter or a recycling business seeking to capitalize on this market, staying informed about pricing trends and industry developments is key to unlocking the potential of scrap catalytic converter trading.